Have any Questions?

Establishment of the company as a small manufacturer of Inline Helical Geared Motors.

Diversified into manufacturing of Brakes for Elevators.

Establishment of our Mira Road Manufacturing Facility having 15000 sq ft of space.

Establishment of a full-fledged Machine Shop having Boring Machines.

Launched our first product line for manufacturing crane duty gearboxes.

Received an ISO 9001 Certification.

Expanded our capabilities with the acquisition of our 1st inhouse Profile Grinding Machine.

Broadened our Product Portfolio to include Helical Gearboxes for Extruder, Screw Jacks.

Received prestigious order from L&T – MHI for manufacturing Turbine Gears.

Upgradation and expansion of our Gear Manufacturing Facilities.

Received multiple orders from the Steel Authority of India for core applications.

1985

Establishment of the company as a small manufacturer of Inline Helical Geared Motors.

2000

Diversified into manufacturing of Brakes for Elevators.

2007

Establishment of our Mira Road Manufacturing Facility having 15000 sq ft of space.

2009

Establishment of a full-fledged Machine Shop having Boring Machines.

2010

Launched our first product line for manufacturing crane duty gearboxes.

2012

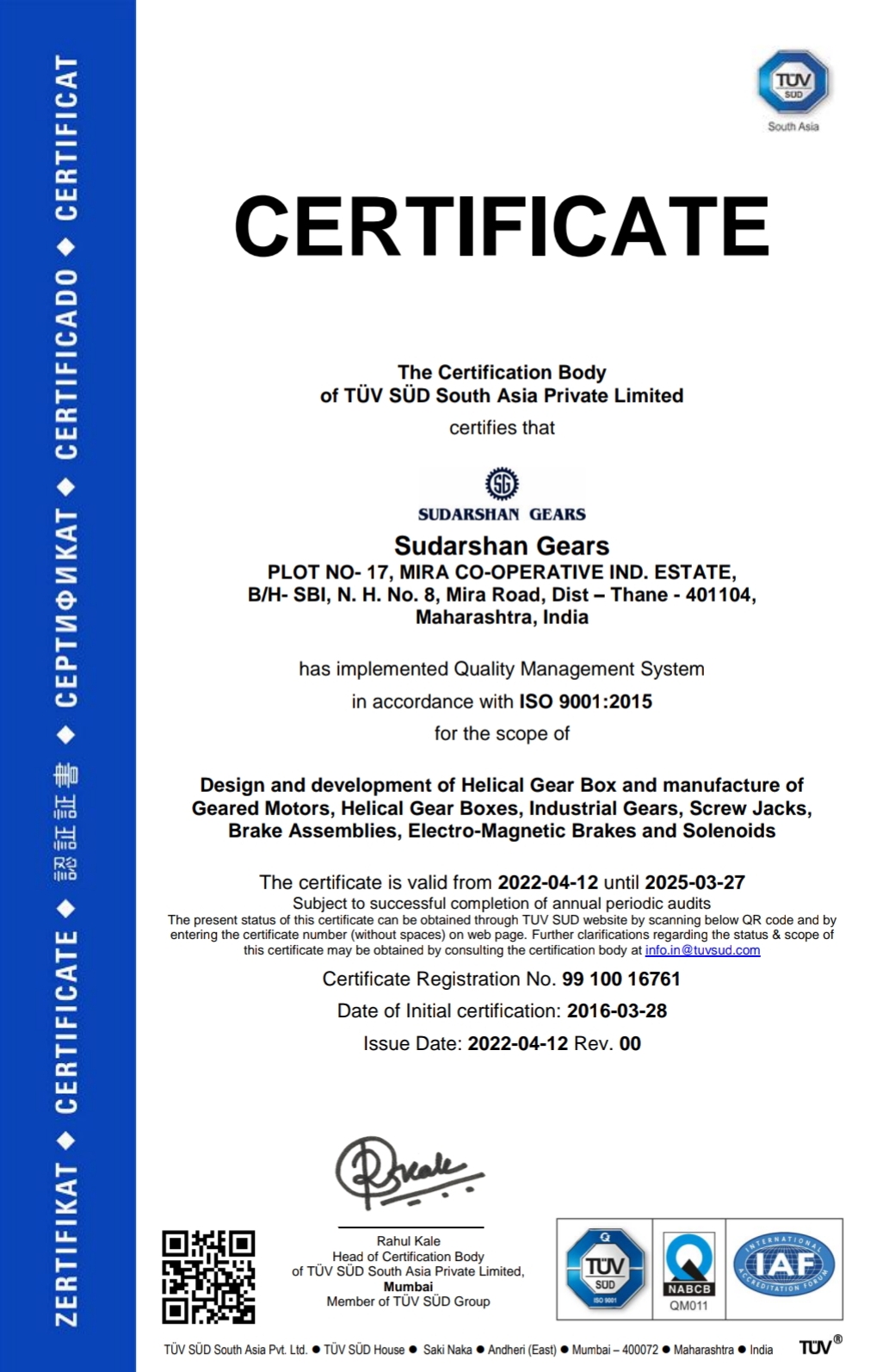

Received an ISO 9001 Certification.

2015

Expanded our capabilities with the acquisition of our 1st inhouse Profile Grinding Machine.

2017

Broadened our Product Portfolio to include Helical Gearboxes for Extruder, Screw Jacks.

2021

Received prestigious order from L&T – MHI for manufacturing Turbine Gears.

2022

Upgradation and expansion of our Gear Manufacturing Facilities.

2023

Received multiple orders from the Steel Authority of India for core applications.

To achieve profitable and sustainable growth. To pursue excellence and innovation through committed team work. To drive success through precision.

To provide customers efficient and enhanced performance. To shine as a global player with achievement orientation and ethical business practices.

By embracing teamwork, open communications, hard work and dedication, we take data-driven decisions to achieve 100% customer satisfaction.

At Sudarshan Gears, we are committed to providing high-quality gearbox products and services to our customers. Our Quality Policy is based on the following principles:

By following these principles, we strive to be a trusted partner for our customers and deliver high-quality gearbox products and services that meet their needs.

QUALITY MANAGEMENT SYSTEM CERTIFICATION: IMS

Our quality management system is designed to meet the requirements of ISO 9001 and other relevant standards, and we will comply with all applicable legal and regulatory requirements. We will strive to minimize waste, reduce costs, and increase efficiency, while maintaining the highest level of customer satisfaction.

Sudarshan Gears boasts a state-of-the-art infrastructure to support its advanced manufacturing processes. Our company has a sprawling manufacturing facility that spans over an area of 15,000 sq. ft. equipped with all the necessary machinery and equipment to ensure the highest level of precision and quality.

The manufacturing unit has a wide range of machines like CNC Hobbing machines, Gear teeth Profile Grinding machines, CNC turning machines, Boring machines, drilling machines, and many more. The machines are designed to produce high-quality gears, shafts, and other allied products, meeting the highest international standards.

We have a dedicated Quality Control department that is well-equipped with advanced instruments like lead and profile testers, gauges, surface finish testers, hardness testers, etc. to ensure that the final product meets the customer’s specifications and requirements.

Moreover, the facility is equipped with modern material handling equipment like cranes, hoists, and forklifts to ensure the safe and efficient handling of products. The manufacturing unit is also supported by a team of skilled and experienced professionals who work relentlessly to ensure timely delivery of products without compromising on the quality.

In a nutshell, Sudarshan Gears’ infrastructure is designed to cater to the diverse needs of its customers, and the company constantly strives to upgrade its technology and equipment to remain at the forefront of the industry.